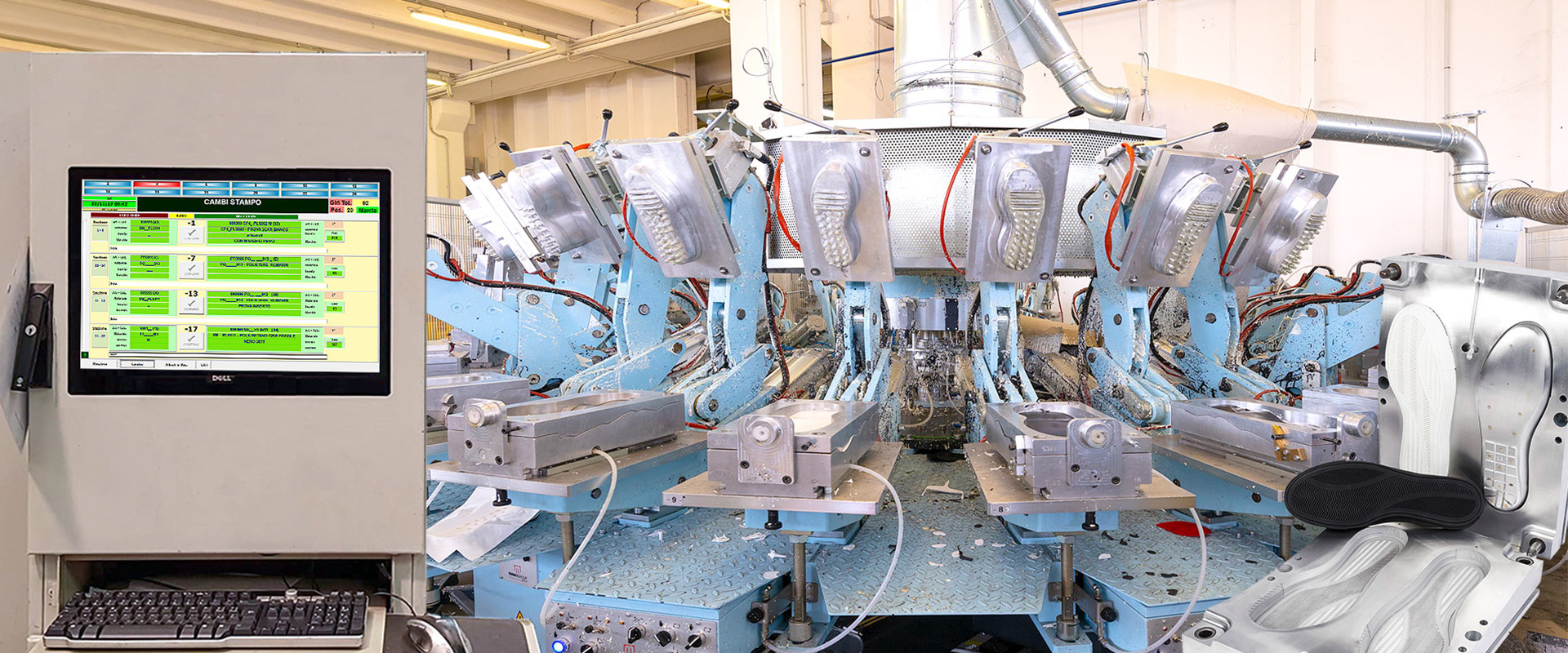

Completely developed within our structure, Polifemo PU summarizes Itaca's ability to develop customized software for a specific production sector.

Polifemo PU allows you to have your own production process under control, to have a constant and precise vision, with the possibility of predictive and final analysis. The software, in fact, offers the possibility of simultaneously acquiring large quantities of data, simplifying the final analysis and making a clear and truth result.

Having been really close to multiple and different customers in the sector, has provided us with the necessary experience that makes Polifemo PU immediately usable by the user.

Polifemo PU is to all intents and purposes an M.E.S. (Manufacturing Execution System) and as such performs all the functions that these types of software are normally required to perform: from scheduling and programming of production for the various stages of the process, to real-time control of the progress of orders, up to a data report for a correct and timely historical statistical analysis.

What really differentiates Polifemo PU from other non-verticalized products for the footwear sector is the size management of the system that manages, simplifies and improves the various working phases.

Functionality and modularity

The structure is modular and therefore functions can be easily expanded while remaining at the forefront both in terms of performance and applicability.

The system "acquires" data from management software (ERP and others), such as, for example, personal data, orders, items, and returns the "products" to it, for the various stages of the process, for a timely alignment of the warehouses, both of raw materials and of semi-finished products and of finished products. We need a Server as a data collector and multiple clients with different access rights depending on user authorization. There is the opportunity to allows “stand-alone” management with local insertion of everything necessary for production.

The production scheduling through the Gantt chart in manual Drag & Drop mode, allows a quick, simple, and intuitive visualization of the programming by machine or work island, reducing errors, optimizing both the number of necessary resources and the relative workload, both set-up, start-up and production changeover times. Each "brick" corresponds to a production batch. The schedule is in real-time updated, according to the actual progress of each individual order, thus checking compliance with the requested delivery date. Semi-automatic multiphase programming is also available with established control criteria to avoid interlocking between the different phases and automatic leveling, through a simple single-level optimization algorithm, which allows the scheduling of each machine to be managed. The logic of the colors of the interface allows you to control the programming according to the criteria chosen by the operator, making the search immediate, by batch, PN, order, raw material, etc. .. It is possible to manage items in the equipment database. Different and with multiple footprints, associated with the same equipment. In the phase of entering orders in programming, it will be possible to associate multiple orders for different items to the same machine, managing their progress.

The planning and scheduling activities take into account the settable and variable machine-department work calendar.

It represents the information center that the department operator sees and the activities that the same can carry out on the single machine.

It allows the user to have an overview of the current situation of the machine with which it is configured; in particular, it provides the ability to know the current configuration of the molds on the various stations, provides pre-alarm in the event of an imminent change and an access point to the native environment of the machine, useful for changing certain parameters in the operation of the machinery.

It can also enter information useful for the proper functioning of the system, including the assignment of the reason for the stoppage, the insertion of rejects with different reasons, the assignment of batches of materials used for complete traceability, etc ...

In fact, in the central column there is a countdown that communicates how many machine revolutions remain before having to make the change, while in the two columns "remove" and "put" respectively we will have information on the current mold and on the next mold to be found.

The system, through the company synoptic, allows a real-time display of the status of the machines connected to the system. The screen allows consultation of the following data for each machine: machine connection status, number of revolutions the machine has reached, the station in which it is at the moment, machine status (running or stopped), total stops of the shift, cycle time of last lap, projection of revolutions per shift, projection of pieces per shift.

Quality Controls are possible by setting specific operational alarms in the database, which are signaled, both on a tablet - PC (or other device), in order to carry out quality checks.

The Maintenance Checks are possible through the machine setting in the "equipment database", with specific operational alarms that are signaled, both on the palmtop and on the PC (or other device), in order to follow maintenance checks on the machines (oil change etc.) or on the equipment (scheduled maintenance).

The intervention, in terms of date - time - operator remain stored in the database for traceability.

Extraordinary

The system allows the extraordinary maintenance management of machines / tools and / or quality controls on articles, requested and made directly by the machine operator, with recording of the intervention history, filterable by time period, article / tool / machine / type of activity. It is possible to noted type of intervention and other specific information.

It is possible to manage documentation in PDF or JPG format, to be displayed in the Client workstations, depending on the type of item / tool / machine, in the ordinary maintenance and quality modules. In detail, the procedure allows you to define, for each item and for each checklist, a series of documents, making them available in the operational phase to those assigned to the various tasks (maintenance and quality)

It is possible to manage documentation in JPG format, to be introduced in the Client workstations, with a special camera or video camera connected to the workstation, depending on the type of item / tool / machine, of both ordinary and extraordinary maintenance and quality management modules. In detail, the procedure allows you to introduce, for each item and for each checklist, a series of images making them available in the consultation phase of the various histories (maintenance and quality).

With Polifemo, it is possible manage and registration of non-conformities.

The application allows the printing management of single or summary labels, collecting the number of pieces per package and the number of packages per pallet in the item database. On the label, the production order, batch and other required codes or parameters are printed. The labeling allows identification for any subsequent phases and processing, for storage, its location and supply chain management.

The system provides a series of historical data reports of production, downtime, rejects, according to an advanced filter search, allowing a subdivision by reason, by machine, by article, by lot, by data, etc.

The historical data tables, as well as being structured as a Pivot, can be exported in standard formats and configurable at the user level.

You will therefore have correct and feedback on the progress of production with all possible data, including downtime and operator actions. The reporting can be customized on specific needs.

It is also possible to calculate the sustainability impact assessment (LCA-LCC).

Optional Features

The latest created in chronological order, Igea Trax, allows, among other things, to contribute interactively to the prevention of COVID19 in companies by managing the proximity of workers to work and the use of personal protective equipment.

mail: info@itacasw.it

Phone: +39 0734.445279

Do you want to request more information or book a free demo?