Do you have a company that wants to grow? With our MES POLIFEMO XE, you can:

- Increase production, reduce waste, monitor machines, and better coordinate your production process

- Optimize your working time… use your time for production and planning, not for troubleshooting

- Increase the speed of production processes and reduce machine downtime

- Gain certainty of time and costs to make consistent estimates and provide immediate responses

Do you need to monitor workflows more closely? With our MES POLIFEMO XE, you can:

- Accurately schedule to improve your productivity times

- Plan departments and resources in the medium/long term

- Know the real-time status of orders and jobs

- Perfectly optimize shifts, maintenance, and quality controls

- Track the productivity commitment of your operators

Do you want to accurately analyze production performances? With our MES POLIFEMO XE, you can:

- Understand which processes are slowing down your production and their causes

- Analyze all critical issues, timings, and process errors

- Guide and correct your staff's work based on data extracted from the system

You can start right away with

The right solution for you!

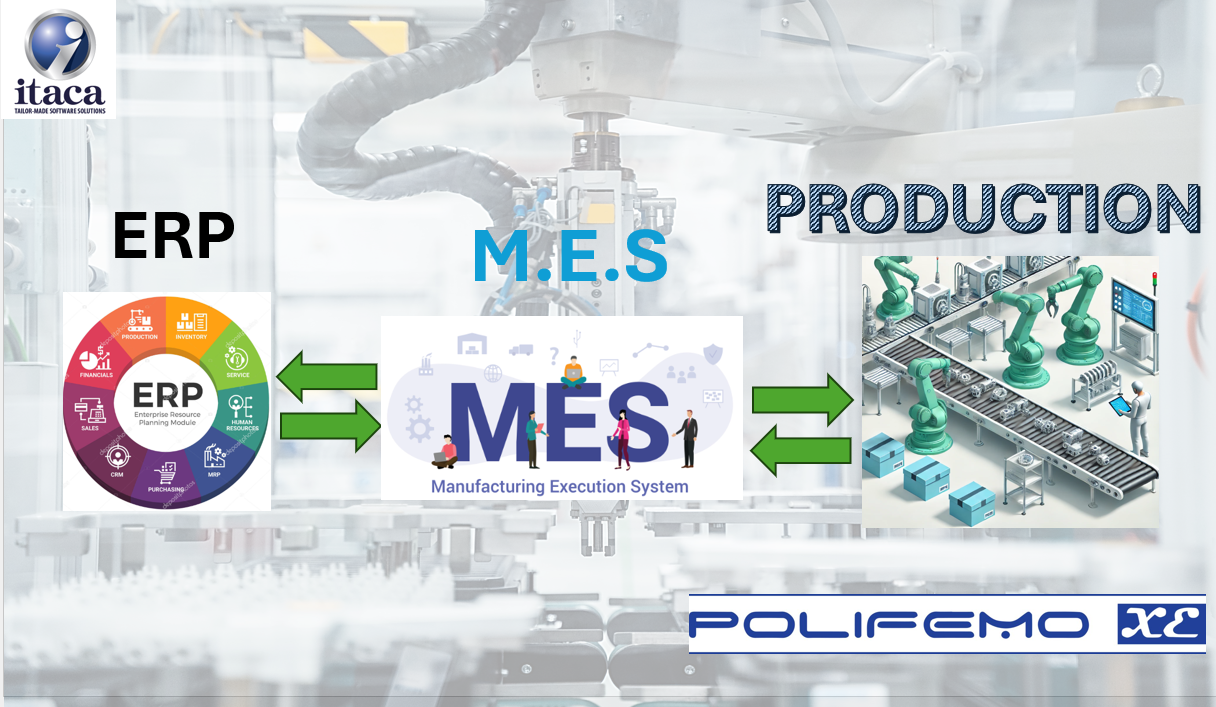

Itaca srl is one of the first System Integrators in Italy to develop systems capable of communicating with industrial machines and interpreting their data for both statistical and management purposes.

POLIFEMO Xe is our M.E.S. solution for scheduling, monitoring, and controlling your industrial processes. It is a product that fully integrates with your software and hardware systems, allowing you to improve operational speeds, reduce waste, and optimize all resources.

POLIFEMO Xe makes companies "Smart" and is an essential component for industrial evolution facilitated by the newly funded Industry 4.0 initiative, fully meeting its specific requirements.

Our applications allow you to:

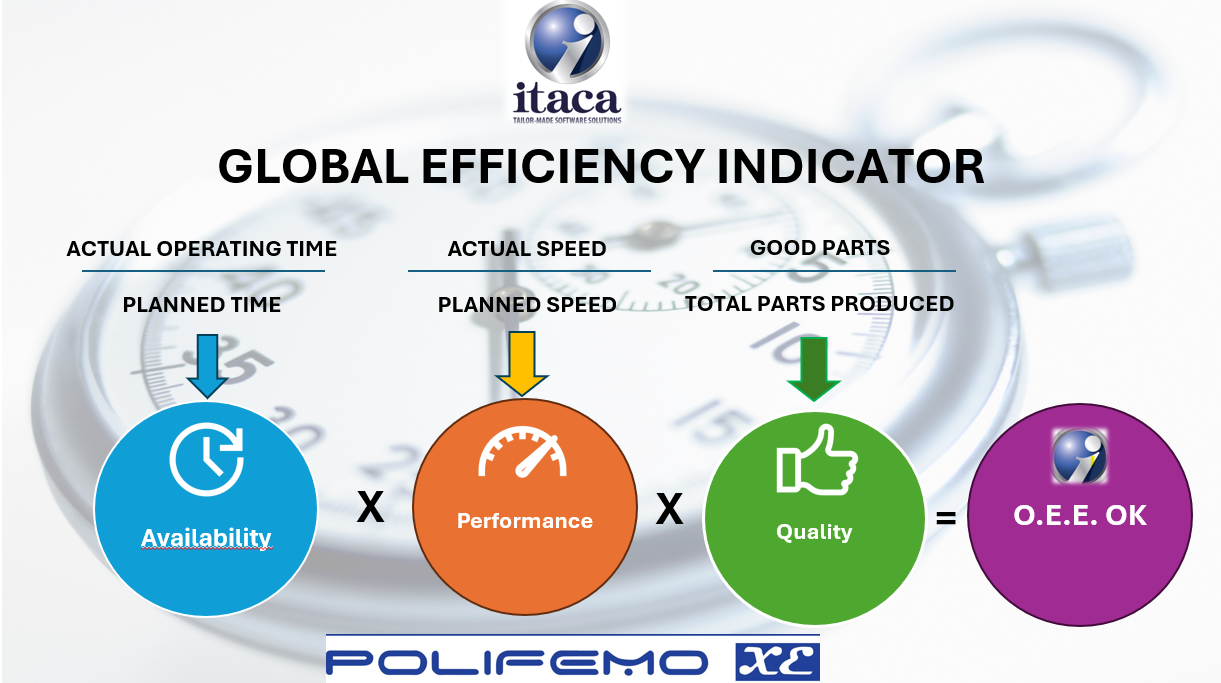

- Test the effectiveness of production processes (O.E.E., KPI, etc.)

- Plan work accurately and consistently

- Increase the operational speed of processes through enhanced controls

- Reduce waste in both materials and human or machine time

- Quickly identify process issues

- Optimize internal and external resources

- Quickly and efficiently address unexpected issue

- Schedule maintenance and shifts

- Have complete traceability of raw and processed materials movements.

- Production cycle analysis.

- Environmental impact analysis and assessment of sustainability (LCA and LCC).

mail: info@itacasw.it

Phone: +39 0734.445279

Do you want to request more information or book a free demo?